This article is being constantly updated with new techniques or things we have learned. If you have any questions please leave a comment and will get back to you. It could help someone else out!

Overview

In this article will go over our anodizing setup and how to anodize your own titanium parts. Anodizing titanium is an electrolytic process that is used to modify the oxide layer on the surface of a titanium part via electric current. Different voltages lead to different thickness of the oxide layer. When light hits the titanium surface, color is shown that corresponds to the layers thickness.

Who is titanium anodizing for?

Anyone who works with titanium that would like to add some color to their parts. Knife makers, watch makers, and many DIY projects benefit from knowing this skill.

Who is this article for?

This was written for any individual or small business that may find themselves wanting to anodize titanium for color. This is a guide based on our personal experiences / setup, so we make no specific scientific claims, and we do not claim responsibility if you injury yourself. Colors ≠ flavor.

Required Materials

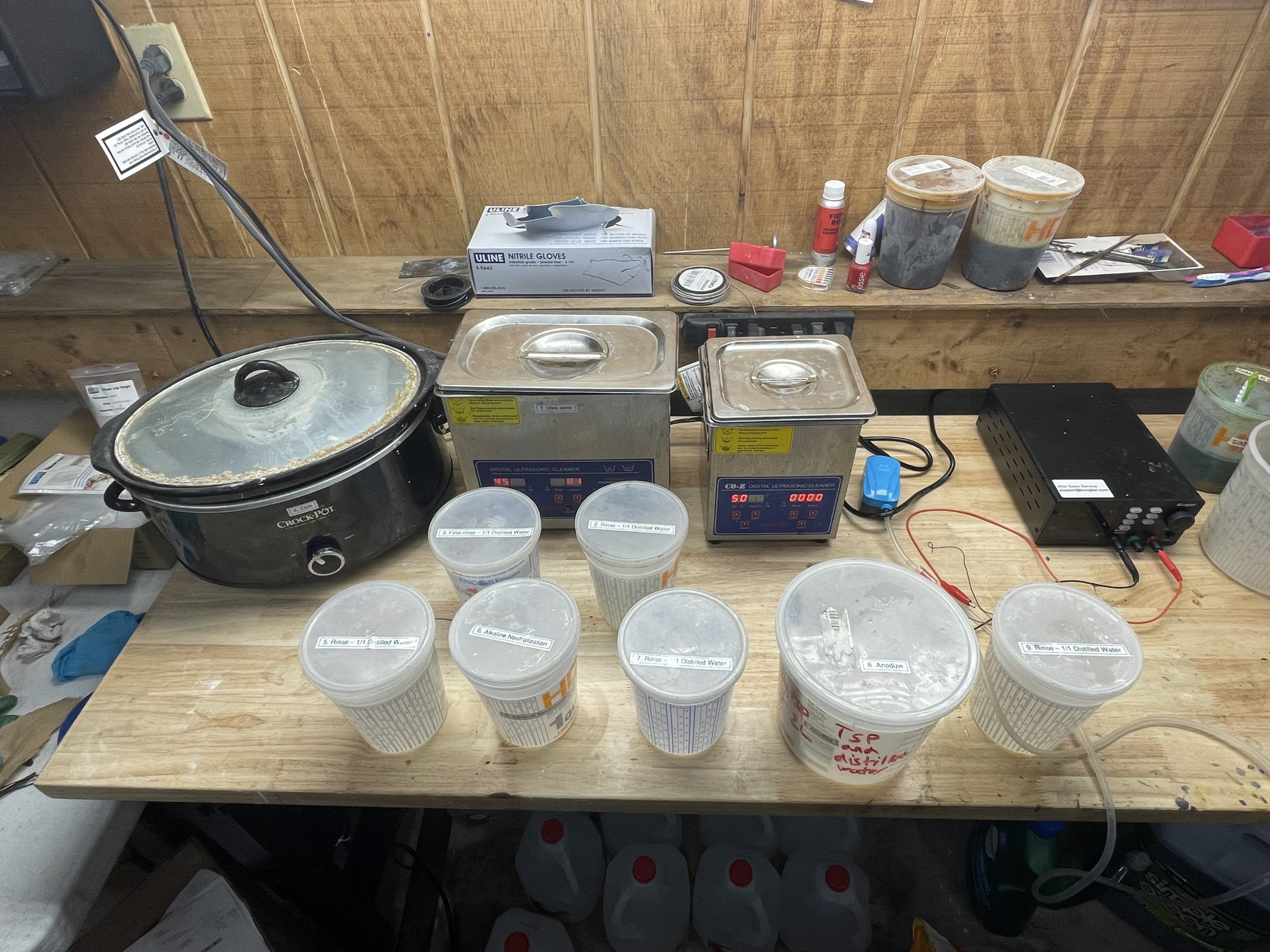

- 1L plastic cups with lids: We use 7 in our setup. We get ours at Home Depot

- 2L plastic cups with lids: We use 1 for our anodizing bath. We get ours at Home Depot.

- Simple Green: For parts cleaning.

- Distilled Water: 8L is a good amount to start with. Water needs to be changed periodically.

- Baking Soda: For alkaline neutralization after etching.

- Trisodium Phosphate (TSP): For the anodizing bath.

- Titanium acid etch: Multi-etch, or follow our guide on making your own.

- A way to heat the acid etch to 60c (140°): Crock Pot is what we use.

- Titanium wire: We use 16ga grade 1.

- DC power supply: We have also used this one with good success.

- Piece of titanium that has more mass then the parts you are trying to anodize, which will be our cathode.

Optional Materials

- Ultrasonic cleaner: Let technology clean your parts. This is the smaller one we also use.

- Soft bristle tooth brushes: For when you want to be the technology that cleans your parts.

- Fish tank bubblier: Helps in keeping contaminants off parts when anodizing.

- Mesh: Prevent touching the cathode during anodizing.

Safety

- Rubber or disposable gloves.

- Safety glasses or goggles.

- Fume hood or respirator.

Setup

Workspace

Get yourself a sturdy work area. A thick wooden topped bench is what we use. We do not recommend using a metal table, because if any of the acid etch touches steel it will rust very quickly. Make sure this area is very well lit, and has access to power outlets.

Take your containers and lay them out. We labeled ours based on step, and what was contained inside, but this is not required.

Containers

- Pre-rinse: 100% distilled water. This will be used to rinse our part directly after cleaning.

- Rinse before acid: 100% distilled water. This will be used to rinse our part of any contaminants that may have been picked up from the previous pre-rinse step. Having two rinse cycles increases the cleanliness of the rinse prior to the acid etch, and decreases the likely-hood of dragging any remaining cleaning agents into the acid etch.

- Acid etch: Take your container of acid etch and place it inside your chosen heating setup. We are using a cheap Crock Pot from Walmart. We placed the container directly on the floor of the Crock Pot. You can fill the Crock Pot with water and use that to “double boil” the acid etch if you desire. Leave the lid on the acid, and leave the Crock pot lid on. Heat the acid etch to 60c (140°), or until small bubbles are visible.

- Post acid rinse: 100% distilled water. Used to pull the bulk of the acid off the part after etching.

- Alkaline neutralization: Distilled water and 15g (0.52oz) of baking soda (small handful).

- Final rinse before anodize: 100% distilled water.

- Anodizing Bath: 2L distilled water, 10g (0.35oz) TSP, titanium cathode submerged with mesh surrounding it so it cannot be accidentally bumped into, fish tank bubblier on, centered and submerged at the bottom of the container.

- Post rinse: 100% distilled water.

Power Supply

In our setup we use a power supply that is capable of supplying 1 – 120v.

Make sure the power is off. Attach a black alligator clipped lead to the power supplies negative output, then attach a red alligator clipped lead to the units positive output.

Take the black alligator clip and connect it to your titanium cathode that is now sitting in your anodizing bath. Power on the unit, and set the voltage to 0v.

Anodizing: Solid Color

In this section we will talk about the steps needed to clean, etch and anodize your part to the color blue.

Prepare Your Part

The surface finish of your part has a large effect on the vibrancy of the colors you get from anodizing. Etching your part will prep the part, but it will not change the overall surface finish. A blasted surface will have a different tone then a tumbled or polished part. The surface finish also changes at what voltage a color is seen on the part. 20v on a tumbled part might be 24v on a blasted part to get the same color.

Clean your part using an ultra sonic cleaner that is filled with distilled water and Simple Green. Make sure to keep the water level of the ultra sonic high.

If you don’t have an ultra sonic, or don’t have time to wait on it to clean, submerge, or spray your part with concentrated Simple Green and gently clean your part with a soft bristle toothbrush. We have found that Simple Green resulted in consistent anodized finishes, is safe to handle, and readily available.

After your part has been cleaned, take some titanium wire and hang your part on it.

- Pre-Rinse: With your clean part attached to some titanium wire, submerge in your part in the first rinse container and gently swirl it around for 5 – 10 seconds.

- Rinse before acid: Submerge the part in your second rinse container and gently swirl it around for 5 -10 seconds.

- Acid etch: Submerge your part in heated acid etch for 8 – 12 seconds. If your part doesn’t appear to be doing anything, the acid etch is probably not hot enough. Leave the part in longer, or remove the part and heat the acid till small bubbles appear.

- Post acid rinse: Submerge your part in the after acid rinse container. Gently swirl for 5 – 10 seconds.

- Alkaline neutralization: Submerge your part and swirl gently for 5-10 seconds.

- Final rinse before anodize: In the last rinse before anodize, submerge and gently swirl your part for 5-10 seconds.

- Anodizing bath: If your power supply is on, make sure it shows a voltage of zero. Attached your negative lead to your cathode (piece of titanium submerged in the container) if you haven’t already done so. Then attach your positive lead to your titanium wire. Submerge your part into the bath making sure that the positive lead is not touching the water. Only the titanium wire and your part should be touching.

- Keeping your part submerged, slowly turn your power supply voltage up to 24v. Observe how the water around your part reacts. You should see very small bubbles appear near your part. Also observe the readout on the power supply. As the part is anodized up to your target voltage the amperage can be shown as high, but once the part reaches your set voltage you’ll notice the amps start to drop. We will wait for the amp draw to plateau and then pull our part.

- Post rinse: Submerge and gently swirl your part for 5-10 seconds.

Your part is now anodized. Take note of the different colors that are shown on the part surface. When your part is wet it may show colors as matte or dull. When the part is fully dry it will show colors as more bright.

When anodizing you should be aiming for what the part looks like when dry. Another thing to keep in mind is what happens when the part is handled. When you get the oils from your fingers on the part, the colors will have a tendency to dull. This can be restored with some water and a small amount of dish soap.